Reliable Biomass Energy Solutions from Bidragon

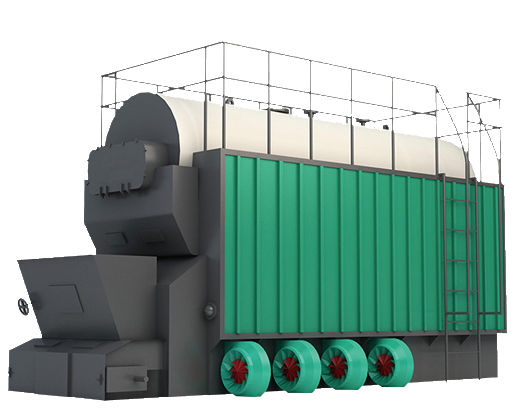

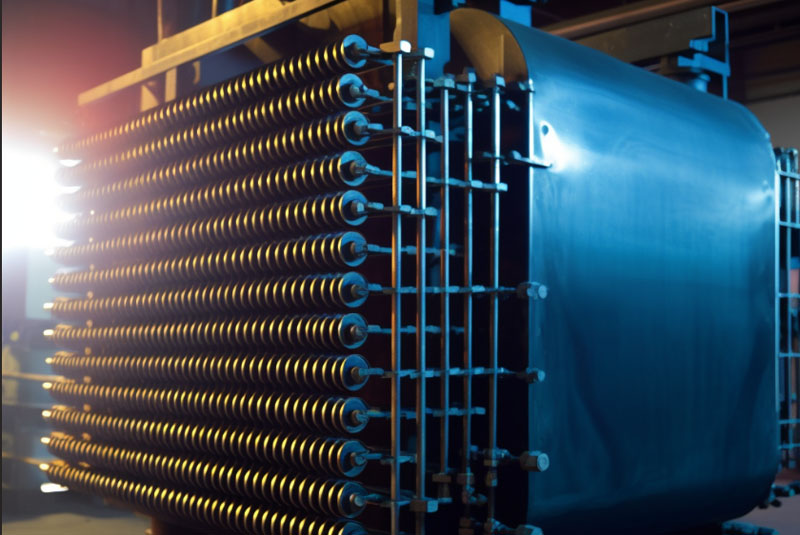

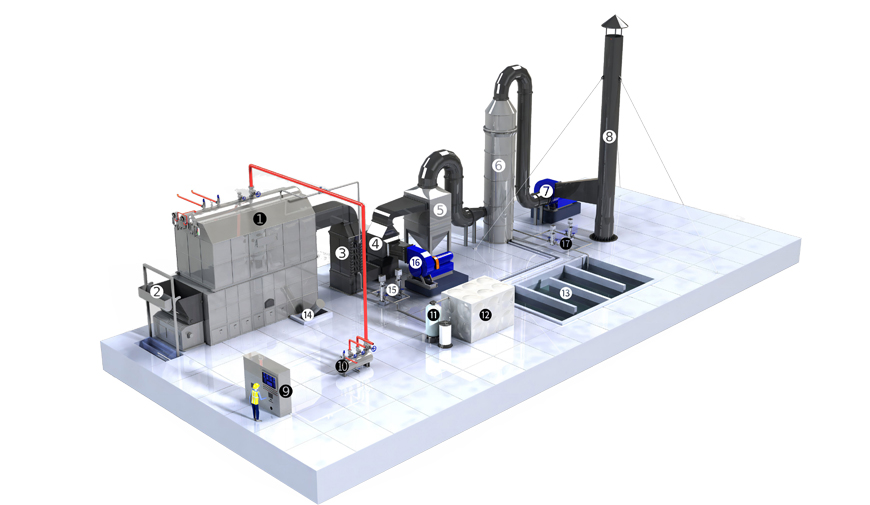

We provide a wide range of boilers, including the DZH, DZL, SZL, DZW, and SZW series of coal-fired steam boilers; biomass steam boilers; jute steam boilers; solid fuel steam boilers; multi-fuel steam boilers; step grate boilers; reciprocating grate boilers; circulating fluidized bed boilers; and waste heat boilers.

Our products are widely used in power generation, heating, chemical industry, textiles, printing and dyeing, construction, plastics, rubber, palm oil processing, wood processing, and many other industries.