.jpg)

Share to:

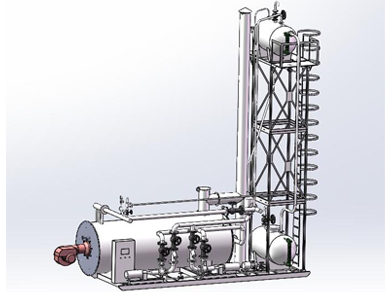

The packaged boiler is compared to the traditional bulk boiler. After the production of the traditional bulk boiler, the boiler body and various components are transported to the site and assembled. The packaged boiler, in addition to the basic components, also includes a base and a bracket. At the time of shipment, each component has been assembled and fixed with the base bracket. After being transported to the site, only the overall installation and connection of the external pipeline are required, and the bulk boiler is relatively bulky. The installation time on the construction site is greatly reduced, and the installation quality of the boiler is also improved. Therefore, the packaged boiler has the following advantages:

1. Compact structure and small footprint

2. Convenient construction and low construction cost

3. High installation quality and good running effect

Note: Due to the volume of transportation, this service is generally only applicable to boilers with a heat capacity of less than 300*104 kcal.

1. Compact structure and small footprint

2. Convenient construction and low construction cost

3. High installation quality and good running effect

Note: Due to the volume of transportation, this service is generally only applicable to boilers with a heat capacity of less than 300*104 kcal.

| Model | YY(Q)- 120Y(Q) (10×104 Kcal) |

YY(Q)- 240Y(Q) (20×104 Kcal) |

YY(Q)- 350Y(Q) (30×104 Kcal) |

YY(Q)- 500Y(Q) (40×104 Kcal) |

YY(Q)- 700Y(Q) (60×104 Kcal) |

YY(Q)- 1000Y(Q) (80×104 Kcal) |

YY(Q)- 1200Y(Q) (100×104 Kcal) |

YY(Q)- 1400Y(Q) (120×104 Kcal) |

YY(Q)- 2000Y(Q) (160×104 Kcal) |

YY(Q)- 2400Y(Q) (200×104 Kcal) |

YY(Q)- 3500Y(Q) (300×104 Kcal) |

YY(Q)- 4700Y(Q) (400×104 Kcal) |

YY(Q)- 6000Y(Q) (500×104 Kcal) |

YY(Q)- 7000Y(Q) (600×104 Kcal) |

YY(Q)- 8200Y(Q) (700×104 Kcal) |

YY(Q)- 9300Y(Q) (800×104 Kcal) |

YY(Q)- 12000Y(Q) (1000×104 Kcal) |

YY(Q)- 14000Y(Q) (1200×104 Kcal) |

||

| Rated Thermal Power kW | 120 | 240 | 350 | 500 | 700 | 1000 | 1200 | 1400 | 2000 | 2400 | 3500 | 4700 | 6000 | 7000 | 8200 | 9300 | 12000 | 14000 | ||

| Thermal Efficiency % | ≥88 | ≥90 | ||||||||||||||||||

| Pressure Mpa | 1.1 | |||||||||||||||||||

| Max. Temp. ℃ | 340 | |||||||||||||||||||

| Circulation Oil m3/h | 12.5 | 20 | 30 | 30 | 60 | 80 | 100 | 100 | 100 | 160 | 200 | 250 | 300 | 340 | 400 | 500 | 600 | 600 | ||

| Pipe DN | 50 | 50 | 65 | 65 | 100 | 100 | 125 | 125 | 150 | 150 | 160 | 200 | 200 | 200 | 250 | 250 | 300 | 300 | ||

| System Power kW | 6 | 9 | 14 | 14 | 22 | 22 | 30 | 30 | 46 | 66 | 85 | 85 | 100 | 130 | 150 | 170 | 230 | 230 | ||

| Fuel | Light oil,liquefied gas, natgas | |||||||||||||||||||

| Fuel | Light Oil (kg/h) | 12.6 | 25 | 35 | 47 | 75 | 98 | 123 | 147.5 | 196 | 245 | 368 | 490 | 613 | 735 | 853 | 980 | 1225 | 1470 | |

| Liquefied gas (kg/h) | 6 | 12 | 17 | 23 | 35 | 45 | 57 | 68.5 | 91 | 114 | 170 | 227 | 284 | 341 | 398 | 455 | 568 | 682 | ||

| Natgas (kg/h) | 15 | 30 | 44 | 59 | 60 | 117 | 146 | 176 | 234 | 292 | 438 | 685 | 732 | 878 | 1024 | 1170 | 1462 | 1755 | ||

| Dimension | Horizontal | Diameter (kg/h) | 1060 | 1012 | 1212 | 1212 | 1400 | 1616 | 1616 | 1816 | 1990 | 2076 | 2162 | 2826 | 3010 | 3400 | 3600 | 3700 | 3860 | 3860 |

| L (mm) | 2045 | 1980 | 2310 | 2722 | 3410 | 3328 | 3903 | 4480 | 4950 | 5300 | 6200 | 6200 | 7400 | 8000 | 8700 | 9400 | 10900 | 13100 | ||

| H (mm) | 1300 | 1287 | 1656 | 1656 | 1880 | 2068 | 2108 | 2414 | 2490 | 2576 | 2662 | 3326 | 3510 | 38000 | 40000 | 41000 | 42000 | 42000 | ||

| Total Weight kg | 1215 | 1355 | 1590 | 1680 | 2715 | 3142 | 3660 | 5420 | 7850 | 8850 | ||||||||||

Product Inquiry