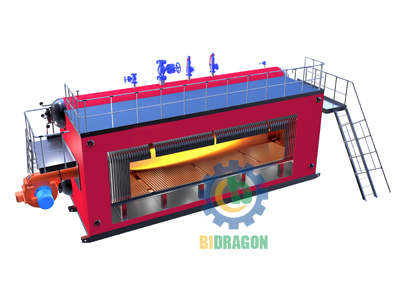

Main Features

1. SZS series gas/oil boiler high temperature area adopts forced circulation to ensure that the heating surface of each part can be reliably cooled and prevent vaporization.

2. SZS series gas/oil boilers are equipped with explosion-proof doors and flame detectors, which are safe and reliable in operation.

3. The seal between the membrane wall on both sides and the drum are all comb-shaped plates, which eliminates the problem of condensate and gas leakage caused by refractory concrete sealing. Before leaving the factory, boilers are tested for air tightness to ensure that there is no slight gas leakage.

4. SZS series boiler has a larger furnace, with ultra-low nitrogen burner, NOx is less than 30mg/Nm3 flue and the boiler flue gas port adopts internal insulation measures, which effectively reduces the noise during boiler operation The combustion chamber adopts a full-membrane water-cooled wall structure and adopts micro-positive pressure combustion, which has no smoke generation problems and no pollution to the operating environment.

5. Adopt high-quality aluminum silicate fiber, and then use refractory cement for heat insulation, the temperature of the furnace body is controlled below 45℃, then the heat loss is effectively controlled.

6. The combustion chamber adopts the narrow-wall tube mode cold wall, which has good air tightness, reduces heat loss, and improves the boiler's thermal efficiency.

7. The inside of the observation hole adopts molded high-aluminum refractory material and manhole sealing device, which changes the problem of overheating this part by refractory bricks.

8. SZS series boilers are equipped with fire viewing holes at the front and back of the upper and lower drums, and an inspection door is arranged at the rear of the boiler, which is easy to open and facilitates user inspection and cleaning of the inside and outside.

9. The front and rear walls of the SZS series boiler body all adopt a membrane structure, which greatly improves the service life of the front and rear walls and ensures a service life of more than 20 years

10. All anti-shake fasteners are used for the convection pipes in the high temperature area to eliminate the fracture problem of the convection tube bundle mouth. Perform 100% radiographic inspection.

| Model | SZS10 | SZS15 | SZS20 | SZS25 | SZS30 | SZS35 | SZS40 | SZS50 | ||

| Rated Evaporation | t/h | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | |

| Rated Steam Pressure | Mpa | 1.25(1.6) | ||||||||

| Rated Steam Temp. | ℃ | 194(204) | ||||||||

| Rated Inlet Water Temp. | ℃ | 20(104) | ||||||||

| Designed Heat Efficiency | % | 92.8 | 92.9 | 93 | 93 | 93.1 | 93.1 | 93.2 | 93.2 | |

| Designed Ambient Temperature | ℃ | 20 | ||||||||

| Weight | T | 30.6 | 40 | 45 | 48 | 52 | 59 | 65 | 70 | |

| Boiler Operating Water Volume | T | 8.2 | 10.8 | 13.3 | 15.4 | 19.5 | 23.2 | 28.6 | 32.5 | |

| Boiler Full Water Volume | T | 10 | 13.5 | 16.3 | 18.6 | 22.8 | 27.5 | 34.5 | 38.6 | |

| Burning Method | Micro Positive Pressure Chamber Combustion | |||||||||

| Natural Gas | Nm3/h | 790.3 (691.1) |

1173.2 (1016.6) |

1545.3 (1342) |

1950.2 (1700.2) |

2340.6 (2035.6) |

2730 (2381.2) |

3115.4 (2710.5) |

3898.2 (3395.6) |

|

| Diesel Oil | Kg/h | 679.3 (599) |

1000 (895.3) |

1323.9 (1161) |

1698.5 (1496.5) |

2039 (1801.2) |

2380.2 (2101.1) |

2705.6 (2385.4) |

3398.4 (2999.2) |

|

| Transportation Size | L | mm | 7700 | 9270 | 9650 | 9650 | 10850 | 11780 | 12820 | 12820 |

| W | 2750 | 3450 | 3530 | 3710 | 3890 | 4150 | 4270 | 4390 | ||

| H | 3680 | 3800 | 3950 | 4050 | 4200 | 4250 | 4300 | 4400 | ||

| Installation Size | L | mm |

9200 | 12340 | 12820 | 12820 | 13860 | 14790 | 15830 | 15830 |

| W | 4478 | 5800 | 6200 | 6450 | 6700 | 7000 | 7300 | 7600 | ||

| H | 4365 | 4450 | 4600 | 4700 | 4850 | 5000 | 5100 | 5200 | ||

| Water Inlet | DN | mm | 50 | 50 | 65 | 65 | 80 | 80 | 80 | 100 |

| Main Steam Outlet | DN | mm | 150 | 150 | 200 | 200 | 200 | 250 | 250 | 300 |

| Secondary Steam Outlet | DN | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Manual Sewage Outlet | DN | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Continuous Sewage Outlet | DN | mm | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Safety Valve | DN | mm | 2*80 | 2*100 | 2*100 | 2*125 | 2*150 | 2*150 | 2*150 | 2*150 |

| Chimney Diameter | mm | Ø800 | Ø 950 | Ø 1100 | Ø 1200 | Ø 1300 | Ø 1400 | Ø 1500 | Ø 1650 | |

| Remark 1: Above all data according to standards of natural gas low position calorific value8400kcal/Nm, diesel low position calorific value 10250kcal/kg. Remark 2: Due to continuous improvement, we reserve the right to modify the appearance& specifications. The above parameters are for reference only, please refer to the final drawing. |

||||||||||