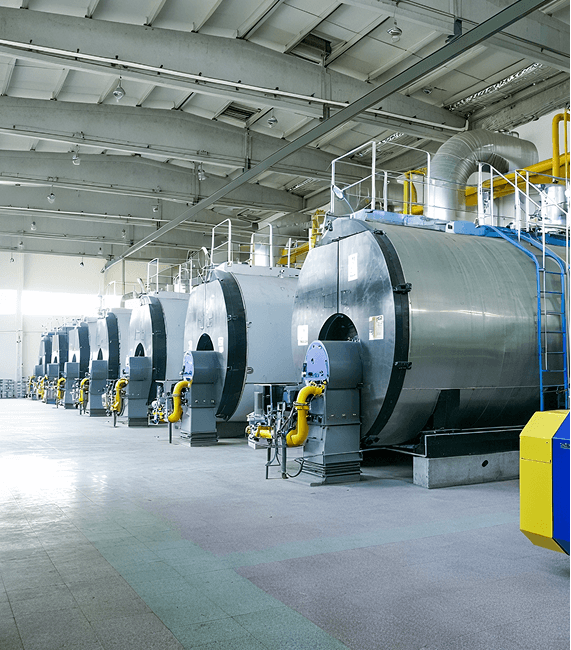

A thermal oil boiler is a special type of industrial furnace that uses heat transfer oil as the thermal medium. The oil is heated by an electric heater and circulated in liquid phase by a high-temperature oil pump. The heat is transferred to the heat-consuming equipment, and the oil returns to the electric thermal oil boiler for re-heating through the oil outlet of the heat-consuming equipment, forming a complete cycle heating system.

Working Principle of Thermal oil boiler

The working principle of a thermal oil boiler is to heat the heat transfer oil using an electric heater. The heated oil is then circulated in liquid phase by a high-temperature oil pump to transfer the heat to the heat-consuming equipment. The system typically consists of the following components:

- Explosion-proof electric heater: Used to heat the heat transfer oil.

- Organic heat carrier furnace: The main heating unit that transfers the heat from the electric heater to the heat transfer oil.

- Heat exchanger (optional): Transfers the heat from the oil to the materials that need heating.

- Heat oil pump: Ensures the circulation of heat transfer oil in the system for continuous heat supply.

- Expansion tank: Regulates the volume changes in the system as the temperature fluctuates.

Types and Characteristics of Heat Transfer Oil

Heat transfer oils are mainly divided into two types: mineral oil-based and synthetic oil-based.

- Mineral oil-based heat transfer oil: Made from a mixture of hydrocarbons, typically used in lower to medium-temperature heating applications. It is usually more cost-effective.

- Synthetic heat transfer oil: Produced through chemical synthesis processes, this oil has a specific chemical structure, offering better thermal stability and a longer service life. It can also be recycled for repeated use.

Advantages and Disadvantages of Thermal oil boiler

Advantages:

- High efficiency and energy savings: Thermal oil boilers are simple to operate, have high temperature control precision, and save energy.

- Safe and environmentally friendly: Compared to steam heating, heat transfer oil heating is safer and more environmentally friendly.

- Wide application range: Suitable for the heating, processing, storage, and transportation of crude oil, natural gas, and mineral oils.

- High maintenance costs: Heat transfer oil is prone to oxidation and thermal cracking during use, leading to oil degradation and aging. Regular replacement and maintenance are necessary.

- Complex operation: First-time users need to perform processes like furnace drying and dehydration. During operation, temperature and pressure need to be strictly controlled to ensure stable performance.

Application Scenarios of Thermal oil boiler

Thermal oil boilers are widely used in various industries that require stable and high-temperature heating. Common applications include:

- Oil refineries: In refineries, thermal oil boilers are often used for preheating cold materials and in heating systems for solvents and extractants in lubricant manufacturing processes.

- Chemical industries: Used for heating raw materials, solvent recovery, and other processes.

- Mineral oil processing: Used for heating, storage, and transportation of mineral oils.

- Food processing: Certain food manufacturing processes also require thermal oil boilers for temperature control and heating.