Steam Boiler VS Steam Generator: A Comprehensive Guide

Steam is used as a powerful energy carrier in a wide variety of manufacturing processes and day-to-day operations in both industry and commerce. From manufacturing in large factories, to sterilization operations in hospitals, to precision experiments in laboratories, steam is everywhere.

When it comes to choosing equipment to generate steam, steam boilers and steam generators are often the main considerations. Although both types of equipment can generate steam, they differ significantly in a number of ways.

This article will provide a comprehensive analysis of steam boilers and steam generators to help you make informed decisions.

What is a Steam Boiler?

Definition and Basic Functions

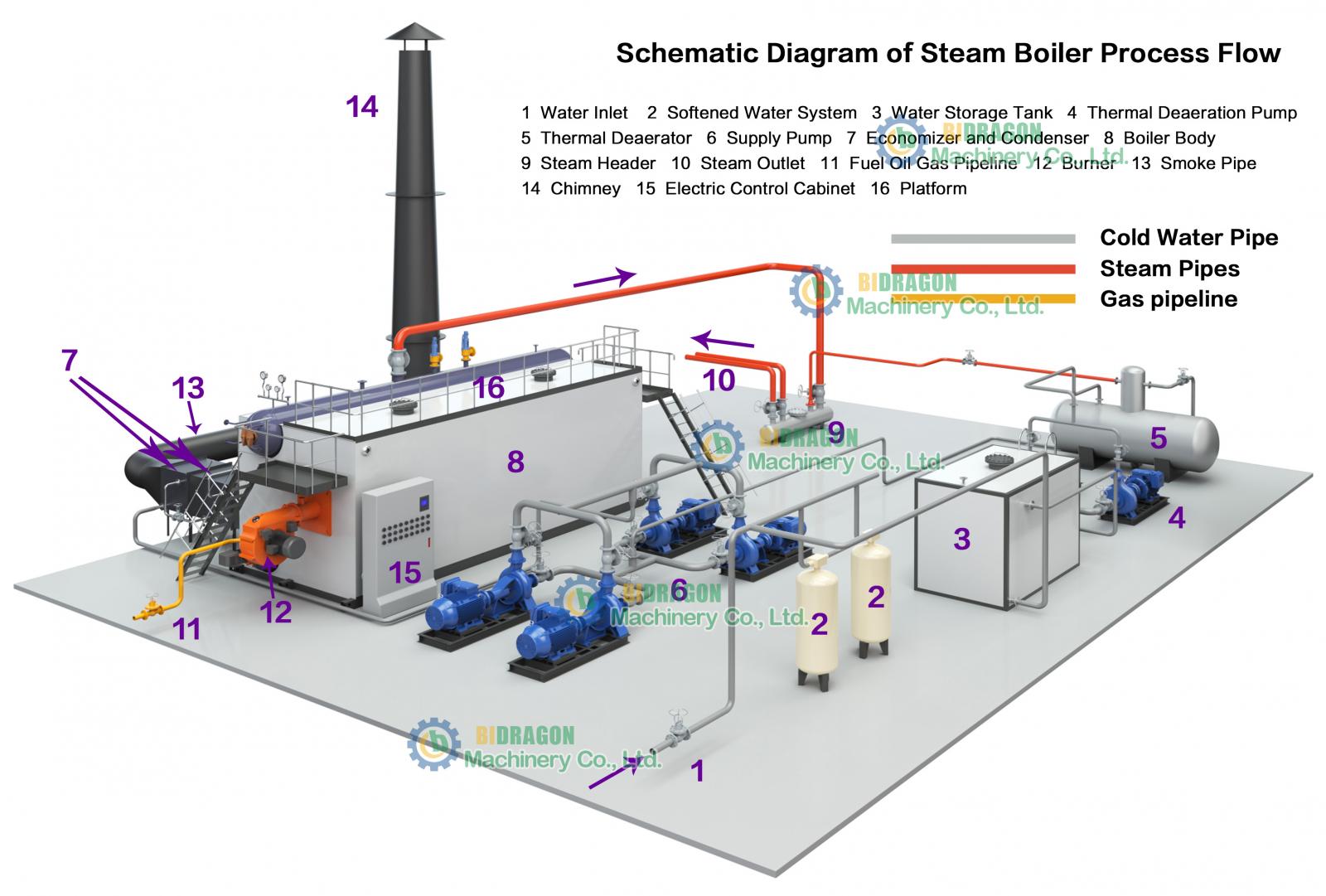

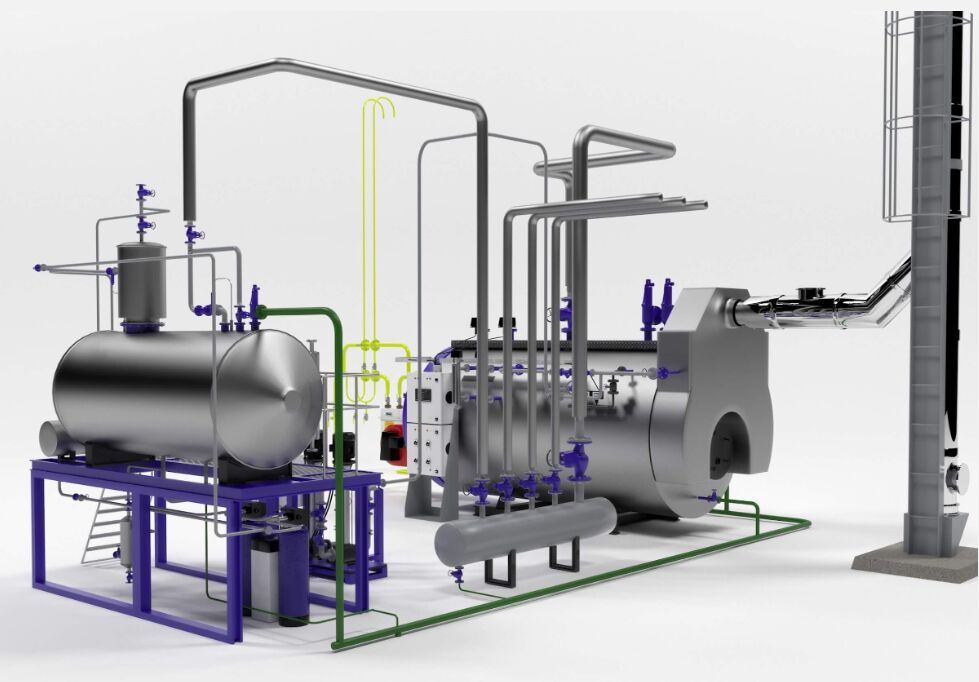

A steam boiler is a system specifically designed to heat water to produce steam, with its core function being to act as a heat exchanger, converting water into steam for external applications. It consists of two main components: a combustion chamber that burns fuel to produce heat, and a water vessel that holds the water and converts it to steam.

Heat Transfer Processes

The process of generating steam in a steam boiler involves three forms of heat transfer: radiation, convection, and conduction. In the combustion chamber, the heat generated by the burning fuel is transferred to the surrounding furnace walls by radiation; the hot flue gases flowing inside the boiler transfer the heat to the heated surfaces by convection; and the heated surfaces transfer the heat to the water inside by conduction, which gradually warms up and eventually vaporizes into steam.

Range of Sizes

Steam boilers come in an extremely wide range of sizes, from small units that are only capable of meeting the needs of small-scale production or localized heating requirements, to large installations that can cope with the intense steam demands of large-scale industrial production. Different sizes of steam boilers have different rated evaporation capacities; for example, a steam boiler with a rated evaporation capacity of 1 ton means that it is capable of generating 1 ton of steam per hour, while large steam boilers can be rated to produce tens of tons of evaporation.

What is a Steam Generator?

Definition and Design

A steam generator is a relatively small and fast-starting device for generating steam compared to a steam boiler, with a relatively simple design that focuses on efficiently heating water and converting it into steam. Its core component is a single stainless steel tube coil into which feed water is pumped in a continuous flow by a feed pump.

Operating Process

As the water moves through the metal coil, hot gases on the outside of the coil transfer heat to the water inside the coil. As the water advances through the coil, more and more heat is absorbed and the temperature gradually increases, eventually being converted to steam and discharged from a single outlet of the steam generator. During this process, excess water that is not converted to steam is collected in a filter for reuse or proper disposal, and excess gas can be discharged through a specific channel, making the process efficient and easy.

Design Features

Most steam generators have a single coil design with a once-through, forced flow characteristic. This design makes steam generators simple to operate and quick to respond to steam demand when producing small to medium volumes of steam.

Key Differences Between Steam Generators and Steam Boilers

Steam Boiler Boiler and Steam Generator Comparison

|

Item |

Qualifications |

Steam Quality |

Vapor pressure |

Water treatment costs |

Start-up time |

Life |

|

Steam Boiler |

Must have a boiler manufacturing qualification to produce |

Good steam quality, sufficient output, sufficient vapor space, can play the role of vapor separation and steam purification, effectively guarantee the quality of steam, stable steam output. |

Up to 22Mpa or more |

10 tons of softened water can be, more than 10 tons of deoxygenated water, the use of the boiler's own steam deoxygenation, low water treatment costs. |

New plenum boiler 8 minutes to reach the rated condition, suitable for stable operation of production. |

20 years |

|

Steam Generator |

No manufacturing qualification required, difficult to regulate |

Steam moisture, poor quality, no vapor space, can not guarantee the quality of steam, the heat is not fully utilized, steam output is not stable. |

Generally no higher than 1.0Mpa, up to 1.25Mpa |

Must reach the pure water standard, high investment and operating costs, once the water quality is not qualified, the tube explosion can not be repaired, the whole scrap! |

3 minutes to the rated condition, suitable for small-scale production |

Designed for 10 years, the average service life of the actual users 2-5 years that burst pipes and other phenomena |

1.Water Capacity

Steam boilers, which are classified by tonnage based on their rated evaporation capacity, have a higher water capacity and are capable of meeting large-scale steam production needs. For example, large industrial steam boilers can produce tens of tons of steam per hour. In contrast, steam generators are small boilers whose water capacity is strictly limited to less than 30 liters to meet the demand for small volumes of steam in specific scenarios.

2.Safety Factors

Steam boilers, as pressure vessels and special equipment, present certain safety risks. When the pressure inside a closed boiler exceeds a critical value, an explosion may occur. It has been estimated that every 100 kg of water released when a steam boiler explodes is equivalent to the energy of a 1 kg TNT explosive explosion. Steam generators, however, are extremely safe due to their unique design, which does not pose an explosion risk.

3.Operating Procedures

Because of the explosion risk associated with steam boilers, their safe operation is critical. Before they are put into operation, they need to fulfill registration procedures and pass strict inspection and acceptance, and can only be operated after passing all indicators. On the contrary, steam generators, as small steam products, do not need to undergo complicated record acceptance procedures and can be quickly put into operation after simple installation and commissioning.

4.Steam Generation Speed

Steam boilers have a large water capacity and a relatively slow heating process, resulting in a long steam generation time. Steam generators, on the other hand, have a small water capacity and are able to absorb heat quickly, resulting in a significantly shorter steam generation time and the ability to meet the urgent need for steam in a short period of time.

5.Thermal Efficiency

The thermal efficiency of different types of steam boilers varies. Taking common fuel types as an example, the thermal efficiency of coal-fired boilers is generally around 75% or even lower; the overall thermal efficiency of gas-fired boilers is about 90%; and the thermal efficiency of biomass-fueled boilers is about 80%. Combining all types of boilers, the average thermal efficiency is about 85%. The thermal efficiency of the steam generator can be as high as 90% or more, and its unique warping heat exchanger can quickly absorb heat, improve fuel utilization, and save more energy.

6.State Regulatory Inspection

According to state regulations, equipment with a water capacity of less than 30L is not considered special equipment and is not subject to state regulatory inspection. The vast majority of steam boilers have a water capacity far exceeding this standard, and are considered to be special equipment subject to strict state regulation and inspection. Steam generators, on the other hand, are exempted from state regulation and inspection because they eliminate potential safety hazards in their structure and principle.

7.Equipment Installation

Large steam boilers require a specialized boiler room, and the design of the boiler room must be undertaken by a unit with professional design qualifications. For oil and gas boiler rooms, the design must also be approved by the relevant authorities. In contrast, steam generators usually do not require a special boiler room.

In the choice of installation location, in addition to considerations such as fire protection and gas access, it also offers more flexibility.

It can be placed close to the terminal equipment according to actual needs to reduce piping, lower heat loss and improve steam quality; it can also be placed on the roof for easy maintenance; for steam equipment that does not require supervision, it can also be placed in the basement or green belt and does not take up floor space.

Energy Efficiency

Steam Boilers

Steam boilers typically exhibit high energy efficiency in large-scale operating scenarios, with thermal efficiencies often exceeding 85%. This enables them to consistently supply large amounts of steam at relatively low energy costs in large-scale industrial production to meet the intense demands of the production process.

Steam Generators

For smaller application scenarios, steam generators offer some energy efficiency advantages. However, when compared to large steam boilers, they may be slightly less fuel efficient, and cannot achieve the level of efficient energy conversion that steam boilers can achieve in large-scale operation.

Cost Considerations

Steam Boilers

Steam boilers have a relatively high initial acquisition cost, largely due to their complex construction, large size, and stringent manufacturing standards. However, in the long run, in large-scale industrial applications, they are cost-effective due to their excellent durability and efficient energy utilization, enabling effective cost control through lower energy consumption and less frequent equipment replacement.

Steam Generators

The low initial cost of steam generators makes them ideal for small businesses or projects with limited budgets. The lower up-front investment reduces the financial pressure on the business, quickly meets small-scale steam needs, and offers significant cost advantages in specific scenarios.

Maintenance

Steam Boilers

Regular maintenance is required to ensure optimal performance and long service life of steam boilers. Maintenance includes a thorough inspection of the equipment, timely cleaning of the interior of dirt and impurities, and replacement of worn parts when necessary. Regular maintenance can identify and solve potential problems in a timely manner, ensuring the stable operation of the steam boiler.

Steam Generators

Maintenance of steam generators is usually easier due to their simpler design and relatively small number of components. Routine maintenance mainly focuses on inspection and cleaning of key components, eliminating the need for complex maintenance procedures and greatly reducing maintenance costs and time investment.

How to choose?

Output and Demand

If a company needs a large amount of steam to meet its production needs, a steam boiler is the best choice due to its large capacity and ability to provide a stable and sufficient supply of steam. For scenarios in which the demand for steam is small, the compactness and flexibility of a steam generator and its ability to produce steam quickly are more suitable.

Demand Fluctuations

Steam boilers are more advantageous when there are significant fluctuations in the steam demand of an organization. Their large size and powerful regulating capability enable them to respond quickly to changes in high and low demand at different times of the year. In contrast, steam generators are relatively less flexible in responding to fluctuations in demand.

Long-term use

From the perspective of long-term industrial applications, steam boilers are often the superior choice due to their high efficiency and durability. Steam generators, on the other hand, while having advantages in terms of start-up speed and space occupation, are more suited to small-scale operations and as auxiliary steam supply equipment.

Advantages of Steam Boilers

Energy Efficient

Modern steam boilers demonstrate great efficiency in converting energy into steam. Through advanced combustion technology and heat exchange design, it is able to minimize energy waste, reduce fuel costs and achieve the goal of energy efficient production.

Widely Used

Steam boilers are widely used in many industries. In the textile industry, it is used for fabric sizing and finishing; in the food industry, it is used for cooking, sterilization and drying; in the chemical industry, it is involved in various chemical reaction processes; in the pharmaceutical industry, it is used for the production of medicines and disinfection of equipments; and in the field of energy, it is used to assist in power generation and so on. In addition, it plays an important role in heating and sterilizing buildings.

Environmentally Friendly Choice

Steam boilers that use electricity or natural gas as fuel can significantly reduce pollutant emissions. Compared to conventional coal-fired boilers, they excel in reducing greenhouse gas emissions and atmospheric pollutants, meeting the stringent environmental requirements of modern society and making them an ideal choice for companies to realize green production.

Rapid Steam Production

Steam boilers have the ability to produce large quantities of steam in a short period of time, which is critical for industrial processes that require a high rate of steam supply. For example, in the high-temperature sterilization of canned food, large quantities of steam need to be available quickly to meet productivity and product quality requirements.

Durability and Long Life

Steam boilers made from high-quality materials offer excellent durability and a long service life. Under normal use and regular maintenance, they can operate stably for many years, providing companies with a reliable supply of steam and reducing the cost and time loss associated with equipment replacement.

Automatic Control System

Advanced steam boilers are equipped with an automatic control system, through which operators can easily and precisely control the boiler's temperature, pressure and steam flow. This automated control not only improves ease of operation, but also ensures that the steam boiler is always operating at its optimum condition, improving the stability of the production process and the quality of the product.

Cost Optimization

steam boilers offer a wide range of fuel options, including solid, liquid, gas and electricity. Enterprises have the flexibility to choose the most cost-effective fuel according to local fuel prices and availability, resulting in effective optimization of production costs.

Advantages of Steam Generators

Quick Startup

One of the greatest advantages of steam generators is their ability to produce steam almost instantaneously. Compared to a steam boiler, it eliminates the need for a lengthy preheating process and greatly reduces waiting time, enabling rapid response to urgent demand for steam on the production line and increased productivity.

Compact Design

Its small size and compact design make it particularly suitable for installation in places where space is limited. Whether in small factories, laboratories, or localized areas of hospitals, steam generators can easily find a suitable installation location without taking up too much valuable space.

Low Cost

The low initial acquisition cost of steam generators makes them an attractive option for small businesses or start-ups with limited budgets. The lower cost investment reduces the operational risk of the business while quickly meeting the basic need for steam.

Application Scenarios

- Laboratories:In laboratories, steam generators are commonly used to sterilize equipment and samples, as well as some experimental processes that require precise control of the amount of steam. Its rapid steam generation and precise control can meet the high quality requirements of laboratories for steam.

- Healthcare:In hospitals, steam generators provide steam support for washing and disinfecting clothes in laundry rooms, food processing in kitchens, and high-temperature sterilizing of medical equipment, ensuring a hygienic and safe medical environment.

- Food and Beverage:In the food and beverage industry, steam generators are widely used in the steaming of food, cleaning of processing equipment, and sterilization and pasteurization of beverages to ensure product quality and safety.

Conclusion

Steam boilers and steam generators differ significantly in terms of functions, features and applicable scenarios. Steam boilers are suitable for large-scale, high-demand industrial production scenarios with high requirements for stability and durability, and are cost-effective and offer performance advantages in the long term, despite their higher initial cost.

Steam generators, on the other hand, are more suitable for small businesses, laboratories, and application scenarios with relatively small and flexible demand for steam, thanks to their quick startup, compact size, and low cost.

When choosing steam equipment, companies should consider the size of their steam demand, the stability of that demand, budgetary constraints, installation space, and long-term operating costs. If you still have questions during the selection process, it is recommended that you consult a professional equipment supplier or engineer, who can provide more accurate advice and solutions based on your specific situation.

We hope that the introduction of this article can help you make a wise decision between steam boilers and steam generators, to provide reliable steam for the production and operation of enterprises.