In a world where industry is booming, the efficient use of energy is becoming more and more critical. In the industrial sector, as a “big consumer” of energy, a large amount of heat energy that could have been utilized is lost because it is not effectively recovered. Waste heat recovery, a highly promising technology, is gradually coming into people's view, becoming a powerful weapon for industrial energy saving and emission reduction, cost reduction and efficiency.

Waste Heat Recovery Basics

Definition of Waste Heat Recovery

Waste heat recovery, in short, is the process of re-collecting and re-utilizing heat energy generated during industrial production that would otherwise be emitted into the atmosphere or discarded. Through this initiative, industrial enterprises can significantly improve their energy utilization efficiency, thereby cutting energy expenses and reducing greenhouse gas emissions such as carbon dioxide, and realizing a win-win situation for both economic and environmental benefits.

Temperature Classification Of Waste Heat

High-temperature waste heat recovery (over 750°F): Waste heat in this temperature range contains very high energy, and the recycling value is huge. It can be used in a wide range of industrial processes that require high thermal energy quality to provide strong power for production.

Medium Temperature Waste Heat Recovery (350 - 750°F): Waste heat in this temperature range also has good recovery potential. It can play an important role in optimizing energy use in many industrial processes.

Low Temperature Waste Heat Recovery (below 350°F): Although the temperature of low temperature waste heat is low, it is still possible to recover it. However, due to the temperature conditions, its application in industrial production is relatively limited.

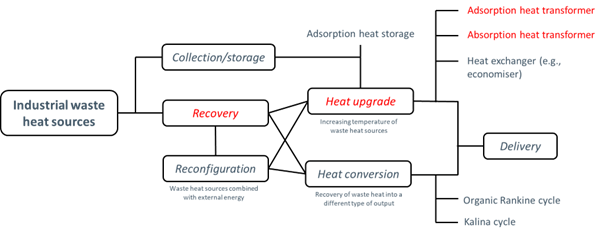

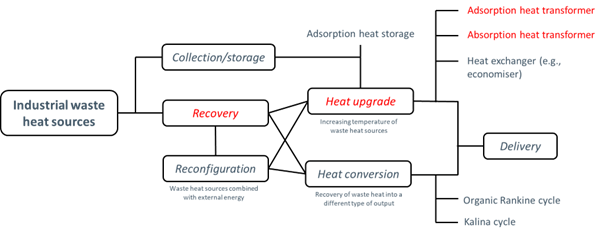

Types of Waste Heat Recovery

Exhaust Waste Heat Recovery

In many industrial combustion processes, such as power generation in power plants, a large amount of high-temperature exhaust gas is generated. Waste heat recovery systems are designed to capture the waste heat from these hot exhaust gases. This is commonly done with the help of heat exchangers or heat reclaimers, which extract the heat from the exhaust gases and reuse it before it is discharged into the atmosphere.

Waste Heat Recovery From Cooling Water

Many industrial production and power generation systems require large amounts of cooling water to carry away excess heat generated by the equipment. Cooling water waste heat recovery systems recover the low-grade waste heat carried by the cooling water through heat exchangers or plate and frame devices. The recovered waste heat can be used for space heating in the plant, preheating of materials, and other low-temperature demand scenarios.

Process Waste Heat Recovery

Various production processes in the manufacturing and chemical industries generate a large amount of waste heat during operation. These waste heat sources are wide-ranging, like hot product streams, reactor jackets, distillation towers, and various other types of process equipment, all of which are “rich mines” of waste heat. Through reasonable recovery techniques, this waste heat can be recycled within the plant, reducing dependence on external energy sources.

Jacket Cooling Waste Heat Recovery

In some specific production processes, engines, compressors, turbines and other equipment need to be equipped with jacket cooling systems to ensure the stable operation of the equipment. The waste heat generated during jacket cooling is not useless. Recovered, it can be used for material preheating, space heating, or even to drive absorption chillers to meet the plant's cooling needs.

Organic Rankine Cycle (ORC) Systems

The ORC system is an advanced technology that specializes in low-grade waste heat recovery. It utilizes a low boiling point organic mass to convert low-grade waste heat, typically below 370°C, into usable electrical energy through a closed loop. This system demonstrates unique advantages in utilizing low-grade waste heat.

Thermoelectric Generator (TEG) System

The TEG system is a solid-state device, based on the Seebeck effect, capable of converting waste heat directly into electrical energy. TEG systems play an important role in application scenarios where there is a demand for direct power generation from waste heat, providing new ideas for solving energy supply problems.

Heat Pump Systems

Heat pump systems use waste heat as a source of energy to drive the refrigeration cycle. Through this process, the heat pump system is able to obtain both heating and cooling functions from the same waste heat source, greatly expanding the value of waste heat utilization.

Waste Heat Recovery System Working Principle

Waste heat recovery boiler is a typical representative of waste heat recovery system. During the operation of the entire boiler system, heat will be lost in many ways, such as flue gas, pipe heat loss, boiler exhaust, as well as warm air from the heated room, and so on. Waste heat recovery boilers make clever use of this dissipated heat to generate additional steam to meet the demands of industrial production.

Waste heat recovery boilers work in a similar way to ordinary boilers, but the heat source does not come from the burner, but from the exhaust gases. High temperature exhaust gases from the production process enter a large chamber from the process furnace. Inside the chamber, the exhaust gases sweep through pipes filled with cold water. Since heat is always transferred from a hot object to a cold object, the heat in the exhaust gases is transferred to the cold water in the pipes, raising the temperature of the water until it reaches the boiling point and is converted to steam. The cooled exhaust gas and the generated steam are discharged from the boiler separately.

The generated steam is transported to all corners of the plant through pipes. On the one hand, it can be used to raise the temperature of the production process to meet process heating needs; on the other hand, the steam can also drive the turbine to generate electricity to support the plant. If the heated exhaust gases do not contain enough energy to completely evaporate all the cold water into steam, an auxiliary burner is activated to supplement the energy and increase steam production.

Importance of Waste Heat Recovery

Improving Efficiency

In today's society, efficiency improvement has always been a topic of great interest. From choosing energy efficient appliances in the home, to choosing fuel efficient vehicles for transportation, people are always looking for ways to live and produce more efficiently. For large-scale industrial manufacturing and production enterprises, the introduction of waste heat recovery systems may seem like a small change, but it can have a far-reaching impact on the overall efficiency of energy utilization, and promote a significant increase in production efficiency from the industry level.

Resource Conservation

The earth's resources are not inexhaustible, in many areas, the rate of resource consumption far exceeds the rate of regeneration. Therefore, for enterprises, especially large-scale enterprises, the efficient use of resources, as far as possible to save resources, should become a top priority in the development process. Waste heat recovery is one of the effective means of saving resources. In some cases, an efficient waste heat recovery system can even completely replace other heat sources, which is significant for the conservation of energy resources.

Reducing Waste

The heating and production processes in a factory inevitably generate waste. Although some waste is difficult to avoid, waste heat, as a special kind of “waste”, can be completely reused rather than simply discarded. Redirecting waste gas and utilizing it as a heat source not only reduces the amount of waste generated by the plant, but also reduces the emission of harmful gases into the atmosphere, contributing to environmental protection.

Typical Examples Of Waste Heat Recovery

Turbocharged Automobiles

In ordinary non-turbocharged automobiles, after the gasoline engine burns fuel, high-temperature exhaust gases are discharged through the vehicle's tailpipe. These exhaust gases not only contain heat energy, but also some kinetic energy. A turbocharged engine, on the other hand, cleverly introduces these exhaust gases into a turbine, which is driven to rotate and in turn drive an air compressor. The compressed air enters the engine combustion chamber together with the vaporized gasoline, making the combustion process more complete, improving the ignition efficiency, and enhancing the power of the car while reducing fuel consumption.

Fuel Economizer

A coal economizer is a common and basic waste heat recovery device that is often used to heat water. It is no stranger to workers in factories. A boiler flue economizer utilizes the heat of exhaust gases exhausted into the flue during the heating process to preheat the boiler feed water. Data from the U.S. Department of Energy shows that installing a boiler feedwater economizer can result in significant energy savings by increasing the thermal efficiency of the boiler and reducing fuel consumption by 5% - 10%.

Waste Heat Boiler (WHB)

Waste heat boilers work on a similar principle to coal economizers and are primarily used to recover waste heat from industrial furnaces or exothermic chemical reactions. At these sites, a large amount of energy would be wasted if it were discharged directly into the flue. Waste heat boilers are able to capture this waste heat and produce steam at low to medium pressure. In addition, waste heat boilers can be used to cool process fluids that need to be transported or stored, and use the heat from the cooling process to generate steam. The steam produced can be used for heating, or to drive a turbine to generate electricity, compress steam, pump liquids, etc. Since steam generated from waste heat boilers may contain a high level of moisture, it is recommended that a combination of a high-efficiency separator and steam trap be installed to ensure the output of high-quality steam.

Waste Heat Steam Generator (HRSG)

Many high-efficiency industrial co-generation or combined cycle systems utilize a gas turbine (similar to a jet engine) to generate electricity, and then convert the waste heat from the exhaust gases from the gas turbine into steam through a waste heat steam generator (HRSG). Take the example of a turbocharged car engine and replace the engine in it with a jet engine. Jet engines burn natural gas to produce high-temperature exhaust gases, and if not utilized, the heat and kinetic energy in these exhaust gases would be vented directly into the atmosphere. With the HRSG, the exhaust gases are introduced to produce superheated steam that drives a downstream steam turbine. The steam turbine can either drive a generator to produce electricity (combined cycle system) or use the steam for process production (cogeneration or combined heat and power system.) The HRSG can be of single-turbine construction or multiple-turbine, multi-pressure-rated construction. Also, there are types without make-up combustion for natural circulation, and types with flue make-up combustion. Flue make-up combustion increases steam production and quality, bringing the steam to a superheated state and thus generating more power at the turbine.

Absorption Chillers

In some energy-efficient cogeneration systems, absorption chillers are introduced to utilize waste heat steam for cooling functions. The operating mechanism of an absorption chiller can be divided into the following stages:

- The diluted absorber liquid (60% lithium bromide salt, 40% water) is preheated by condensate as it flows from the absorber to the generator.

- Inside the generator, the absorber liquid is heated by steam, causing some of the water to evaporate and the concentration of the absorber liquid to increase.

- The concentrated absorbent flows back to the absorber and continues to absorb water, completing the cycle. At the same time, the evaporated water vapor enters the condenser.

- In the condenser, cooling water to liquefy the water vapor, liquid water flows downward to the evaporator, the evaporator is close to the vacuum state.

- Before entering the evaporator, the liquid water flows through a throttling orifice or expansion valve, where the flow is restricted and vaporizes again into a cold mist at 4.5°C (40°F), which is the onset stage of the refrigeration process. The cryogenic mist absorbs heat from the chilled water circuit, lowering the chilled water temperature by about 5°C (9°F).

- The temperature of the mist rises as it absorbs heat from the chilled water circuit, but the strong attraction of the concentrated salt solution to the water draws the vapor into the concentrated absorber solution in the absorber, creating a near-vacuum pressure in the evaporator during this process.

Vapor Heat Compression

Vapor thermal compression is another form of waste heat recovery that utilizes energy from otherwise wasted low-pressure steam. The process uses vapor compression equipment, such as TLV's SC system, to mix high-pressure steam with low-pressure steam to produce intermediate-pressure steam for efficient waste heat recovery.

Benefits of Industrial Waste Heat Recovery Systems

Savings in Fuel Consumption

By capturing and reusing waste heat, companies can significantly reduce their consumption of new energy sources such as electricity and natural gas. Reduced energy consumption not only translates directly into cost savings, but also helps companies move towards a more sustainable development path.

Reuse Of Harmful Emissions

Some of the waste gases produced in industrial production are toxic and cannot be released directly into the environment without proper treatment, such as incineration. By utilizing a waste heat recovery system, companies can reuse the waste heat of these incinerated exhaust gases, turning waste into treasure and improving the productivity of the factory while reducing pollution.

Selling Carbon Credits

With the increasing environmental awareness and the implementation of carbon emission policies, companies that reduce their carbon emissions through waste heat recovery can earn carbon credits. These carbon credits can be sold to other companies or organizations that have a need to reduce carbon emissions, creating a new source of income for the company and promoting the green development of the industry as a whole.

Eligible for financial support

Waste heat recovery systems are highly eligible for state and federal funding programs due to their positive impact on reducing carbon emissions. Enterprises investing in waste heat recovery systems have the opportunity to receive various types of funding from the government, including subsidies, tax credits, loans or rebates, etc., reducing the pressure of upfront investment.

Waste Heat Recovery Application Areas

Power Plants

Power plants, especially those based on fossil fuels or nuclear energy, are the main beneficiaries of waste heat recovery systems. Waste heat recovery power plants capture excess heat from exhaust gases, steam, or cooling water that would otherwise be released into the atmosphere. This recovered heat can then be converted into additional electrical energy through steam turbines or other power generation cycles, increasing the efficiency of power generation.

Manufacturing

In many manufacturing industries, such as steel production, glass manufacturing, cement production, etc., large amounts of heat are released due to the high temperatures involved in the production process. Waste heat recovery systems capture this excess heat and reuse it to preheat furnaces, generate steam for various process needs, or provide space heating for plants, reducing energy costs.

Vehicle Exhaust Systems

Modern vehicles, especially those with internal combustion engines, have begun to utilize waste heat recovery systems to capture heat from the exhaust gases. This heat can be used to preheat intake air or fuel to improve engine efficiency, or to power auxiliary vehicle systems such as air conditioning.

Chemical Processing Plants

The high-temperature reaction and distillation processes in chemical processing plants generate large amounts of waste heat. Recovering this waste heat can be used to preheat incoming raw materials, generate steam for other processes, or even drive absorption chillers to meet the plant's cooling needs, optimizing energy use in chemical production.

How To Determine The Suitability Of AWaste Heat Recovery Boiler

Waste heat recovery boilers come in a variety of sizes, and their dimensions and capacities can be flexibly adjusted according to the actual needs of the enterprise. They are widely used in many industries, such as ferrous metals, non-ferrous metals, chemical industry, oil refining, glass, and any other fields that have an additional demand for steam.

It is important to note that a waste heat recovery boiler only generates steam when the production process is in operation; it is a supplement to an existing boiler system, not a replacement. Although waste heat recovery boilers can be expensive to install, because they eliminate the need for a combustion process and reduce the need for maintenance of equipment such as soot blowers, operating costs are dramatically reduced and can provide a quick return on investment for a company.

Conclusion

Waste heat recovery technology shows great potential and advantages in improving energy utilization efficiency, conserving resources, and reducing waste and environmental pollution. It covers a variety of recovery types and has a wide range of application scenarios in many industries. Both large industrial enterprises and emerging manufacturing plants should actively consider introducing waste heat recovery systems. Through this initiative, enterprises can not only reduce operating costs and enhance their competitiveness, but also contribute to global sustainable development and realize the synergy between economic and environmental benefits.