For the Pakistani market, given its need for efficient, environmentally friendly industrial boilers and the critical period of energy transition, here are a few new boiler types that not only meet the needs of local industrial development, but can also support the development of clean energy:

Biomass Boiler:

6 tonne SZL woodchip fired steam boiler: this boiler adopts high-efficiency combustion technology, using woodchips as fuel, reducing dependence on traditional fossil energy sources, while significantly reducing emissions of carbon dioxide and other greenhouse gases. It has the advantages of strong fuel adaptability, high combustion efficiency, stable operation, etc. It is suitable for food processing, textile and other industries.

Thermal Oil Boiler (Organic Heat Carrier Boiler )

Bidragon's YLW Series Organic Heat Carrier Boiler: This boiler has a rated heating capacity of 9,400KW, with sufficient output to fully meet the high temperature heating needs of Pakistan's textile industry. This type of boiler can be used with a variety of fuels and provides a stable heat source while reducing exhaust emissions.

Waste Heat Recovery Boiler:

Our company provides a new type of patented coking waste gas waste heat boiler: this type of boiler features high efficiency heat transfer, two-stage furnace soot separation, compact and novel structure, low cost, small footprint and high efficiency, environmental protection, energy saving and so on. It can help companies effectively utilise waste heat from the production process, improve energy utilisation and reduce operating costs.

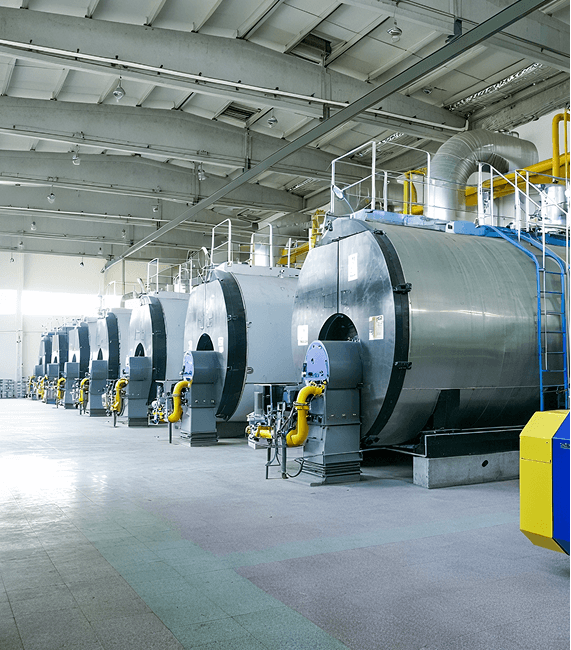

Gas Fired Boiler:

Industrial natural circulation gas-fired steam boilers: suitable for using liquefied petroleum gas (LPG) as fuel, these boilers are compact in design, easy to install, simple to operate and low maintenance. They typically have high thermal efficiency and can respond quickly to load changes, making them ideal for application scenarios that require flexible adjustment of steam output.

Circulating Fluidised Bed Boiler:

Horizontal circulating fluidised bed hot water boilers: these boilers feature the ability to use a wide range of solid fuels, including coal, biomass, etc., and achieve better combustion efficiencies and lower pollutant emissions through optimised combustion processes. This is a good option for businesses looking to switch from traditional fuels to cleaner alternatives.

Chain Grate Boilers:

Hot sale high quality industrial chain grate boiler coal fueled steam boiler: This boiler has showrooms in several locations around the globe, allowing users to easily access the product and receive support and service. It is suitable for a wide range of industries, such as chemical plants, providing a reliable and cost-effective solution.

These new boilers will not only meet the needs of Pakistan's current industrial development, but also help it achieve its energy transition goals of gradually reducing its dependence on traditional fossil fuels and increasing the proportion of renewable energy sources, while ensuring continuity and stability of production. The selection of the right boiler should take into account the specific needs of the organisation, budgetary constraints and long-term environmental impact.