Characteristics:

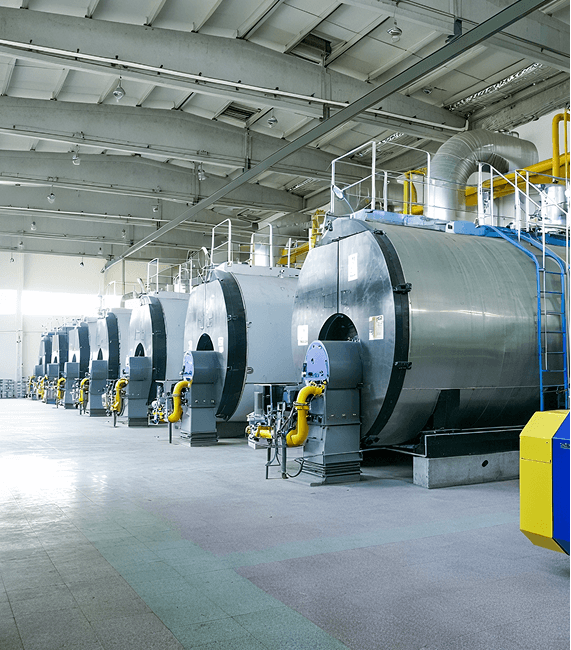

Low Pressure Operation: Unlike steam boilers, organic heat carrier boilers operate at significantly lower pressure, typically below 10 bar. This reduces the risk of explosions and simplifies the boiler design and piping system.

High-Temperature Capability: They can achieve temperatures up to 350°C, making them ideal for demanding industrial processes requiring high heat input.

Heat Transfer Oil: Instead of water, organic heat carrier boilers utilize a specialized heat transfer oil as the heating medium. This eliminates the need for complex water treatment systems and reduces the risk of corrosion and scaling.

Precise Temperature Control: The boiler system allows for precise temperature control, crucial for many industrial applications where consistent heat is essential.

Closed-Loop System: The heat transfer oil circulates in a closed loop, minimizing heat loss and improving energy efficiency.

Advantages:

Safety: Low pressure operation and the absence of high-pressure steam significantly enhance safety compared to traditional steam boilers.

Efficiency: The closed-loop system and efficient heat transfer oil minimize energy losses, leading to lower operating costs.

Versatility: Organic heat carrier boilers can be fired with various fuels like natural gas, oil, and biomass, offering flexibility in fuel selection.

Low Maintenance: Compared to steam boilers, they require less maintenance due to the absence of high pressure and water treatment systems.

Environmentally Friendly: The closed-loop system and efficient combustion minimize emissions, making them a more environmentally friendly option.

Thermal Oil Boilers have a wide range of applications in various industries due to their ability to provide high-temperature heat transfer at low pressure. Here are some of the key areas where they are commonly used:

1. In industry, heating of crude oil and natural gas and processing, storage and transportation of mineral oil. The oil refinery uses heat transfer oil to preheat the cold material, and it has been successfully used to heat the solvent and extractant evaporation devices in the lubricating oil manufacturing process.

2, chemical industry, used for distillation, evaporation, polymerization, condensation/demulsification, fatification, monotony, melting, dehydrogenation, forced insulation, and heating of synthetic equipment such as pesticides, intermediates, antioxidants, surfactants, and fragrances.

3. Oil industry, used for heating of oil synthesis, fatty acid distillation, fatification, nitrification, hydrogenation reaction, concentration, vacuum deodorization, etc.

4. In the food industry, it is used for heating bread baking devices, biscuit food baking devices, confectionery consumption devices, grain monotonous devices, edible oil extraction and refining devices, distillation pots, autoclaves, and conveyor belt dryers.

5. Textile printing and dyeing industry, used in monotone setting device, hot melt dyeing device, dyeing printing device, monotonizer, dryer, calender, flattening machine, washing machine, cloth rolling machine, ironing machine, hot air stenter And other heating.

6. In the medical industry, it is used for the heating of equipment and devices such as medicine preparation, raw material mixing, configuration, disinfection, distillation, evaporation, melting, etc.

7. Fiber industry, used for polymerization, melting, spinning, thermosetting, fiber finishing, stretching and heating of monotonous equipment. In the paper industry, it is mainly used for the heating of glue rollers, monotonous rolls, monotonous rooms, monotonous cabinets, hot melt machines, wax melting pots and corrugated paper processing.

8. In the papermaking industry, it is used for the heating of glue rollers, monotonous rolls, monotonous rooms, monotonous cabinets, hot melt machines, wax melting pots and corrugated paper processing.

9. Plastic and rubber industry, used for heating and heat preservation of hot pressing, hot extension, extrusion, kneading, banburying, vulcanization molding, radiation injection molding machine, glue mixer, conveyor belt dryer, screw extruder and mold.

10. Wood industry, used for the heating of fiberboard, particleboard, laminate, plywood, veneer and wood drying equipment, monotonous equipment, coating equipment and gluing machine.

11. In the building materials industry, it is used for gypsum board drying, concrete components solidification maintenance and prefabrication production, ceramic tile die, decorative material drying and linoleum production line heat.

12. Road construction, used for asphalt heating, dissolution, asphalt storage tank, asphalt concrete and emulsified asphalt heating and heat preservation.

13. Foundry industry, used in metal degreasing tank, acid irrigation, pickling tank, cleaning tank, electroplating tank, Luyang plate oxidation tank, electrode manufacturing, shower heat treatment device, phosphate treatment equipment, baking room, sand core drying Drying, varnish spraying and heating of monotonous, assembled disposal devices.

14. Electrical equipment industry, used for centralized or decentralized heating in factories, offices, hospitals, civil buildings, hotels; polishing machines, rolling mills, vacuum machines, dryers, monotonous chambers, and vacuum chambers in electrical equipment manufacturing .

15. Paint industry, used in autoclaves, monotonic machines, distillation irrigation, evaporation equipment, paint drying, baking, monotonous and high-temperature curing heating.

16. Coking industry, used for heating and heat preservation of gas storage tanks, mixing stations, and distribution stations.

17. Coking industry, used for heating and heat preservation of gas storage tanks, mixing stations, and distribution stations.

18. Automobile manufacturing industry, used for heating tunnel-type drying rooms, degreasing baths, and phosphoric acid treatment equipment.

19. Carbon industry, used for graphite electrodes, carbon products, asphalt coagulation, kneading pot heating, extrusion molding heating.

20. In the maritime industry, it is used for heavy oil tanks, asphalt tanks, sulfur tanks on ships and containers that require heating and insulation.