In this article, we will explore the key aspects of maintaining and caring for a thermal oil heater to prevent costly downtime and extend the lifespan of the system.

1. Regular Inspection of the Heater System

Routine inspections are critical for identifying potential issues early and ensuring the efficient operation of the thermal oil heater. A comprehensive inspection should include the following components:

- Burner System: Check the burner for any signs of wear, blockages, or malfunction. Regularly clean and calibrate the burner to ensure proper combustion.

- Oil Circulation: Inspect the oil circulation system for leaks, blockages, or any signs of wear. A consistent flow of oil is vital for efficient heat transfer.

- Heat Exchanger: Ensure that the heat exchanger is clean and free from debris or fouling. Heat transfer efficiency depends on the cleanliness of the heat exchanger surfaces.

- Piping and Valves: Check the condition of all connecting pipes and valves for leaks or corrosion, as these can significantly affect the system's performance.

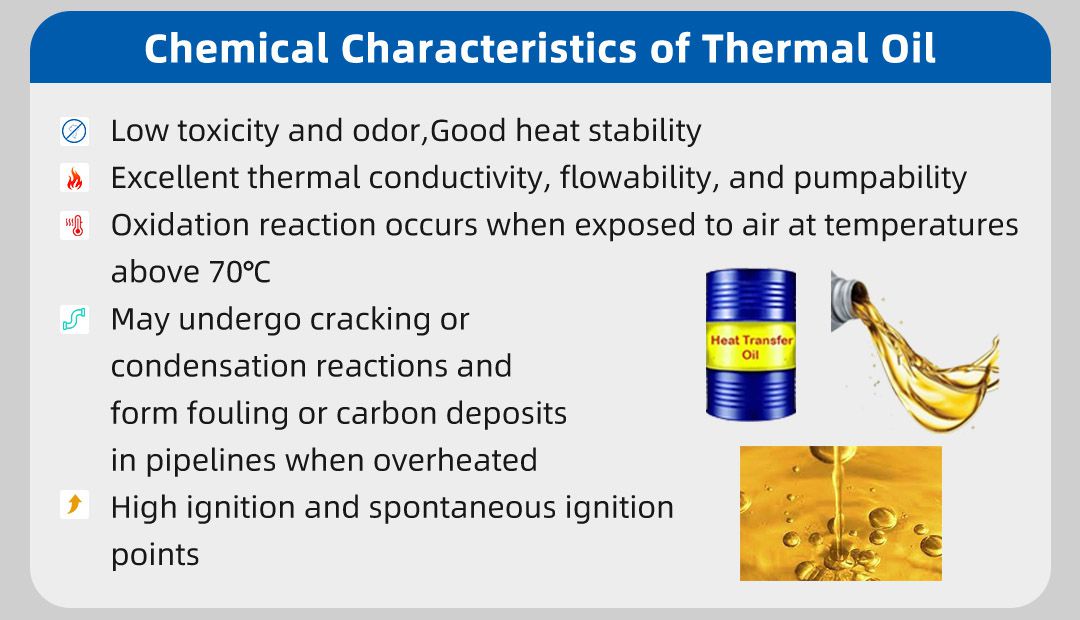

The thermal oil used in the system plays a crucial role in heat transfer and system efficiency. Over time, thermal oil can degrade, leading to reduced heat transfer capabilities and increased energy consumption. To maintain optimal performance:

- Monitor Oil Quality: Test the thermal oil regularly for contaminants such as water, sludge, or acids. If the oil is found to be degraded, it should be replaced promptly.

- Check Oil Levels: Regularly check the oil levels in the system. Insufficient oil levels can result in overheating and damage to the heater components.

- Oil Filtration: Use oil filtration systems to prevent impurities from entering the thermal oil, ensuring smoother operation and reducing wear on the components.

3. Cleaning and Descaling

Maintaining clean surfaces is essential for heat exchange efficiency. Over time, deposits from oil, dust, and other materials can accumulate on the heat transfer surfaces, reducing efficiency. Implementing a cleaning schedule is critical for optimal performance.

- Periodic Cleaning: Clean the heat exchanger surfaces and burner areas on a regular basis to remove soot, scale, and other build-up.

- Descaling: If scaling has occurred in the heat exchanger or pipes, descaling should be performed to restore the heat transfer efficiency.

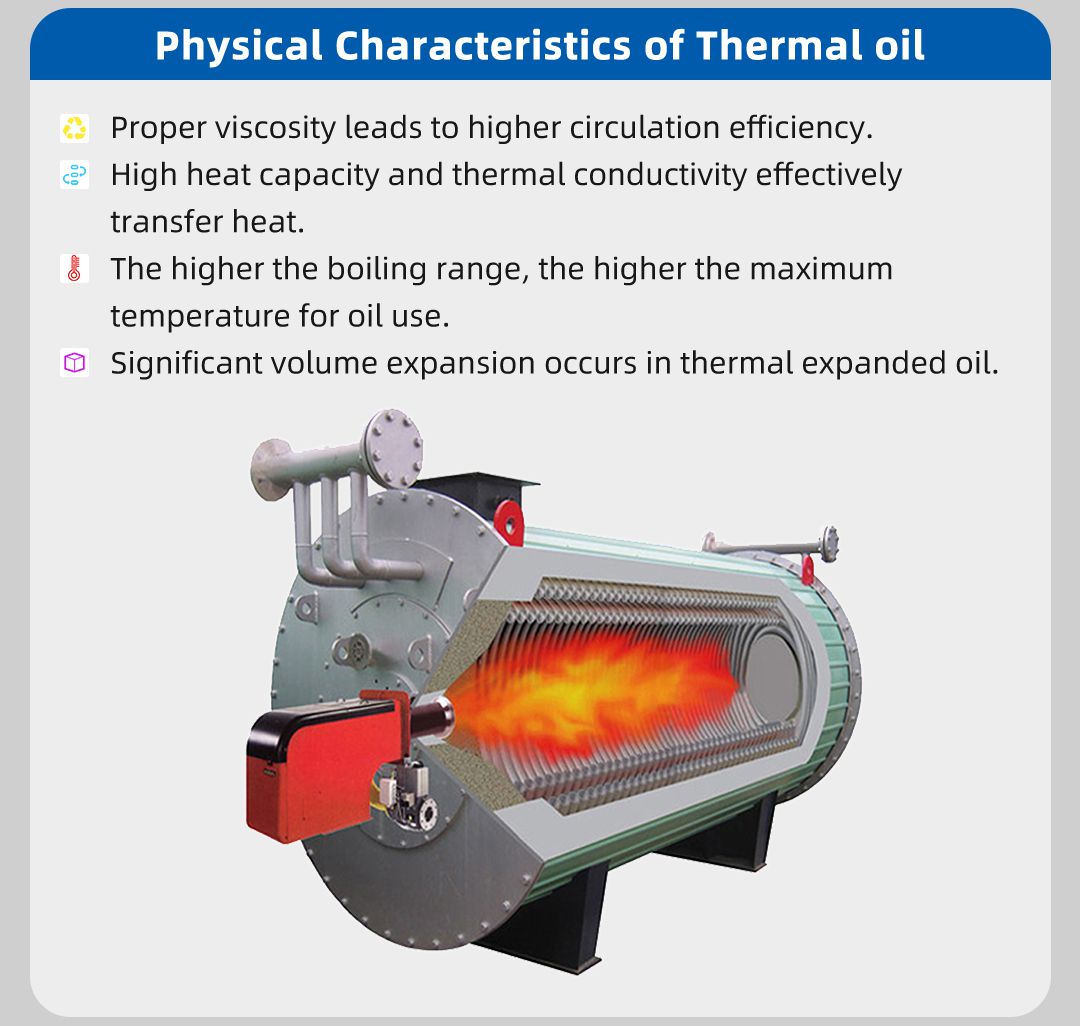

Thermal oil boiler operate under high temperature and pressure conditions, and any deviations can result in damage or system failure. Install reliable temperature and pressure gauges to monitor the system's performance.

- Temperature Monitoring: Ensure that the temperature does not exceed the recommended levels for the thermal oil. Overheating can cause oil breakdown and equipment damage.

- Pressure Checks: Regularly monitor the pressure within the system. High or fluctuating pressure levels can indicate problems within the system, such as blockages or valve malfunctions.

While operators can handle day-to-day maintenance, it is crucial to schedule professional servicing at least once a year. Qualified technicians can conduct a more thorough inspection and perform tasks such as:

- Checking the integrity of the heat exchanger and other critical components.

- Calibrating and testing the burner and control systems.

- Ensuring that the safety systems, such as pressure relief valves and safety shut-off systems, are functioning correctly.

Thermal oil boiler operate at high temperatures and involve complex systems. Safety should always be a priority during maintenance activities.

- Training for Operators: Ensure that all personnel are properly trained in the safe operation and maintenance of Thermal oil boiler.

- Emergency Procedures: Develop and communicate emergency procedures for dealing with potential failures or accidents.

- Personal Protective Equipment (PPE): Ensure that all maintenance personnel use appropriate PPE, including gloves, goggles, and heat-resistant clothing.

Proper maintenance and care are essential for ensuring the reliable and efficient operation of Thermal oil boiler. By regularly inspecting and maintaining critical components, monitoring oil quality and system performance, and scheduling professional servicing, industries can prolong the lifespan of their equipment, reduce operational costs, and minimize downtime.

Investing in the proper maintenance of your thermal oil heater not only improves the performance of the system but also enhances safety and minimizes the risk of unexpected failures.