Business Background

The pharmaceutical industry is an important field related to human life and health, and has very high requirements on the environment and hygiene. As an indispensable equipment in the pharmaceutical industry, boilers can not only provide high-temperature steam for decoction of traditional Chinese medicine, medicinal materials drying, boiling glue, drug production and other technological processes, but also play a role in high-temperature disinfection for medical appliances and medical supplies. When choosing boilers produced by major manufacturers, the quality of the steam produced by the boiler and whether it can output high-temperature steam efficiently, stably and continuously is very important. Compared with coal-fired boilers, natural gas boilers are more environmentally friendly, energy-saving, and easy to use. favored by the industry.

In the process of drug production, raw material processing, sterilization and drying, and compression into capsules or tablets all require a steam boiler to provide high-temperature steam; at the same time, the steam boiler can also be used as a power to drive the normal operation of the equipment. However, due to the special nature of the pharmaceutical industry, the pharmaceutical process has very high requirements for steam, and it is necessary to stabilize the output and ensure the quality of the steam.

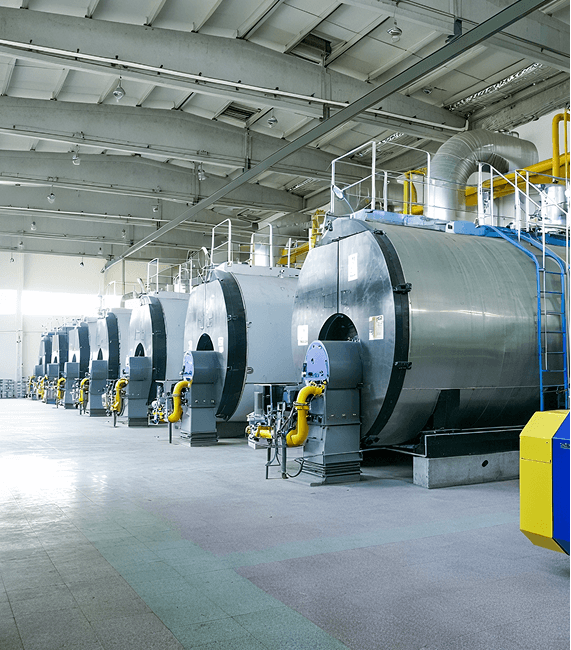

The company that cooperated with BIDRAGON this time is a multinational company. The company is mainly responsible for the Central Asian markets such as Uzbekistan and Russia. At present, a drug production line with a certain scale has been formed in Uzbekistan. The company's project leader first got in touch with BIDRAGON through the Internet, and under our warm invitation, a week-long visit to the factory. BIDRAGON's technicians and boiler instructors accompanied the whole process, and introduced the 120,000-square-meter boiler manufacturing base, R&D center, laboratory and other sites in detail to the customer. The customer was trusted by BIDRAGON's professional and responsible attitude, and finally determined a boiler Low nitrogen gas steam boiler (WNS4-1.25-YQ) with output of 4 tons. The boiler is an integrated design, which greatly saves the overall floor space, and is very convenient for transportation and installation; at the same time, we also provide a complete set of boiler auxiliary machinery, installation, export, transportation, and special personnel to guide the installation, etc. Service, one-step more assured.