Our latest DZH6 Multi-fuel Steam Boiler has arrived in Bangladesh and is currently undergoing the unloading process. This state-of-the-art Steam Boiler is set to provide reliable and efficient energy for a leading garment company in the region. Our dedicated local installation team will soon commence with the installation and commissioning, ensuring that the boiler operates at peak efficiency for the customer's specific needs.

The success of our products in the region—especially our Biomass Steam Boilers and Jute Steam boilers—has made them the preferred choice among local entrepreneurs. In this article, we will explore the features of the DZH6 Multi-fuel Steam Boiler and how it will support the growth of Bangladesh's garment industry.

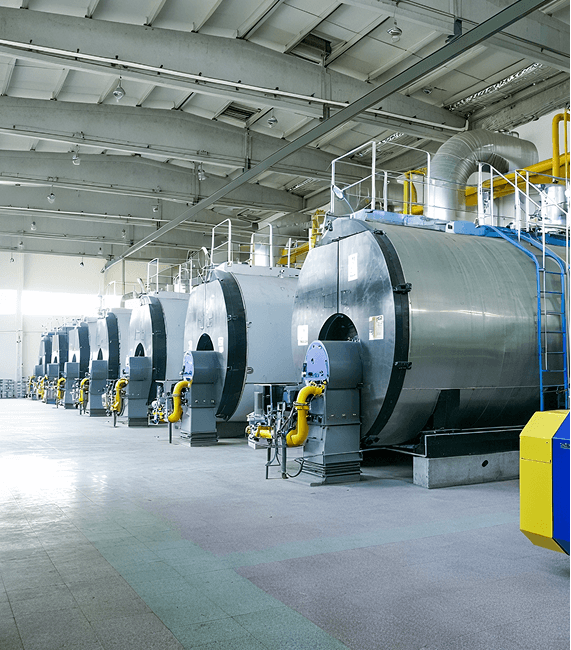

The DZH6 Multi-fuel Steam Boiler is designed with flexibility and performance in mind. This robust boiler can operate on various fuel types, including coal, biomass, and other alternative fuels, providing a versatile solution for industries with different energy needs. The ability to use multiple fuels offers significant cost savings and ensures the boiler's adaptability in changing fuel markets.

Key features of the DZH6 include:

Multi-fuel Capability: The ability to burn coal, biomass, and other renewable fuels makes this model ideal for businesses seeking a sustainable energy solution. High Efficiency: The DZH6 is engineered for optimal heat transfer and low energy consumption, ensuring that the garment company can reduce operating costs while maintaining high productivity levels. Compact Design: Its compact design allows for easy integration into existing facilities, minimizing installation time and disruption to business operations. Durability and Reliability: Built with high-quality materials, the DZH6 offers long-term reliability and minimal maintenance needs, ensuring smooth and continuous operation.The multi-fuel capability of the DZH6 is especially beneficial in a region like Bangladesh, where biomass and other alternative fuels are widely available. It provides a sustainable and cost-effective solution that is both environmentally friendly and economically advantageous.

The Role of Steam Boilers in the Textile and Garment IndustrySteam boilers play a critical role in the textile and garment industries by providing a reliable source of heat and power for manufacturing processes. These industries rely heavily on steam for dyeing, drying, and finishing fabrics, as well as for powering other machinery in the production process. As a result, the efficiency and reliability of steam boilers directly impact the overall productivity and cost-effectiveness of textile and garment companies.

In Bangladesh, a country known for its thriving textile and garment sectors, the demand for reliable and efficient steam boilers is increasing. The DZH6 Multi-fuel Steam Boiler is an ideal solution for companies looking to meet this demand while also reducing their energy costs. By utilizing a combination of coal and biomass, businesses can significantly reduce fuel expenses, especially in regions where these resources are abundant and affordable.

Customer Success Stories in BangladeshOur steam boilers have already made a positive impact in various textile and garment companies throughout Bangladesh. Notably, our biomass steam boilers and jute steam boilers have gained significant popularity due to their efficiency and environmental benefits. Local entrepreneurs recognize the long-term value these boilers bring to their businesses, helping them reduce energy costs while improving their production capabilities.

One example of a successful installation is at a large textile manufacturing facility in Dhaka. The company had previously faced issues with unreliable boilers that caused frequent downtimes. After switching to our biomass steam boiler, they experienced a dramatic improvement in operational efficiency, reduced maintenance costs, and a significant decrease in fuel consumption. The company has since expanded its use of our steam boilers across multiple facilities in the region.

Another success story involves a garment company based in Chittagong, which installed one of our jute steam boilers. The unique advantage of using jute as a fuel source—an abundant and inexpensive resource in Bangladesh—has allowed the company to significantly cut down on fuel costs while contributing to the sustainability of local agricultural practices.

The Installation and After-sales SupportA key factor in the success of our steam boiler installations in Bangladesh is our local installation and after-sales support team. Our team is composed of highly trained professionals who are well-versed in the installation, commissioning, and maintenance of our products. The team will work closely with the garment company to ensure that the DZH6 Multi-fuel Steam Boiler is installed efficiently, safely, and in accordance with local regulations.

Once the boiler is installed, our team will conduct thorough testing to ensure that all systems are functioning properly. This ensures that the customer can begin operations with confidence, knowing that their new boiler will perform reliably.

Additionally, we provide ongoing support to our clients, offering regular maintenance services and troubleshooting assistance whenever needed. Our commitment to after-sales service ensures that the steam boiler continues to operate at peak efficiency throughout its lifecycle, minimizing downtime and maximizing productivity.