Meeting the needs of the textile industry

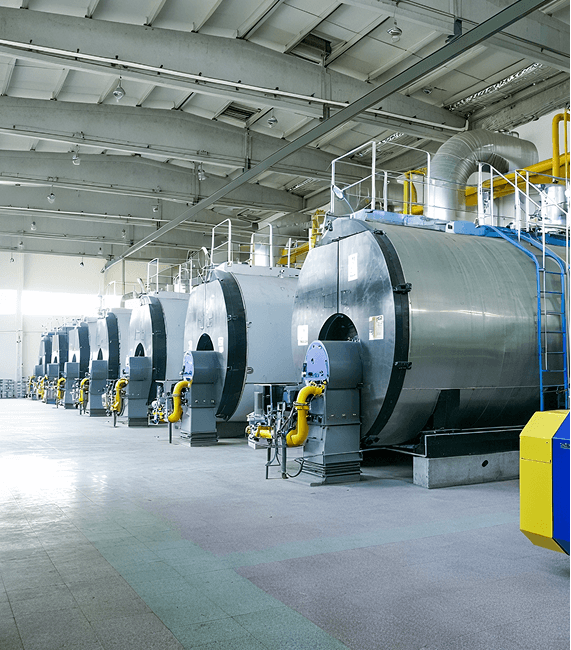

The customer's primary requirement was for a reliable and efficient steam generation system to support its dyeing and printing processes. The dyeing and printing stages of textile manufacturing are of critical importance, as they have a significant impact on the quality and durability of the final product. The introduction of a charcoal-fired steam boiler has not only met but exceeded these requirements, ensuring a consistent steam supply, temperature control and operational efficiency.

Versatility with multi-fuel capability

One of the outstanding features of this boiler is its multi-fuel capability(Multi Fuel Boiler). Designed to operate on a variety of fuel sources, including coral, charcoal, biomass and biomass pellets, the boiler offers exceptional flexibility and reliability. This versatility is particularly beneficial in regions where fuel supply and costs can vary, allowing customers to optimise operating costs by switching between different fuel types as required.